Back in May 2025, a plastic’s expert from Mikrocentrum, lectured a training about Thermo and vacuum forms, here at Aerofilm. The ultimate goal of this training was to share knowledge and insights within our team, in order to improve our Polyurethane air casters production process.

From theory to practice

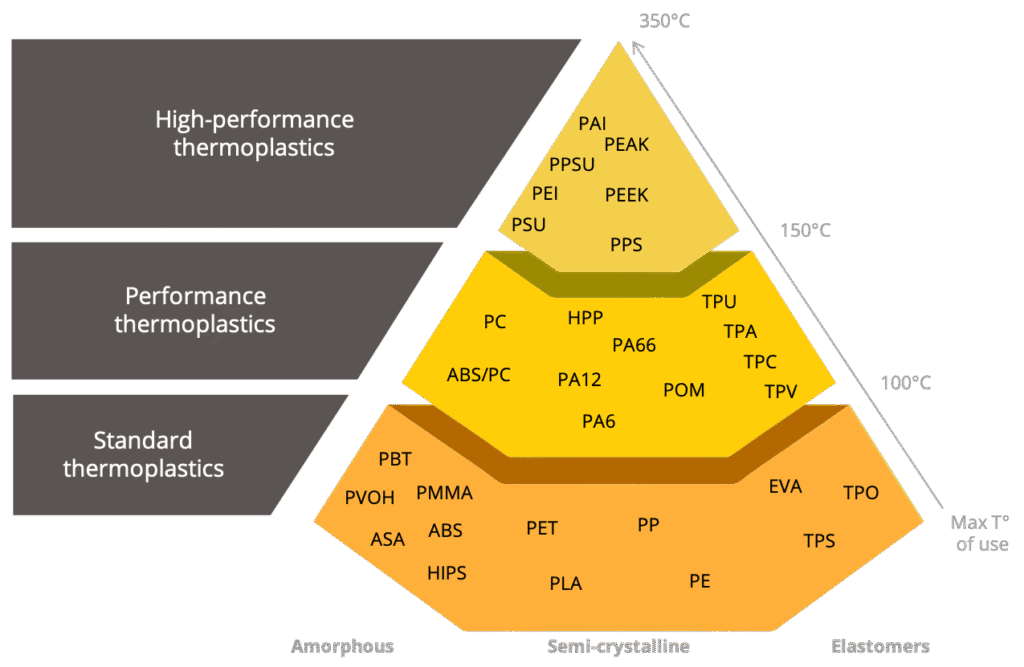

To better understand the materials we work with on a daily basis, we started by exploring the science behind plastics:

- classification of thermoplastics;

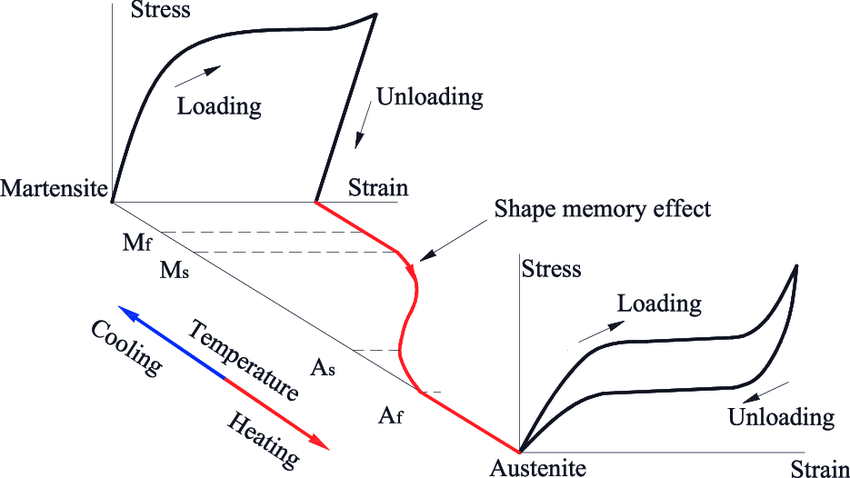

- how thermoplastics respond to heat;

- what defines their elasticity;

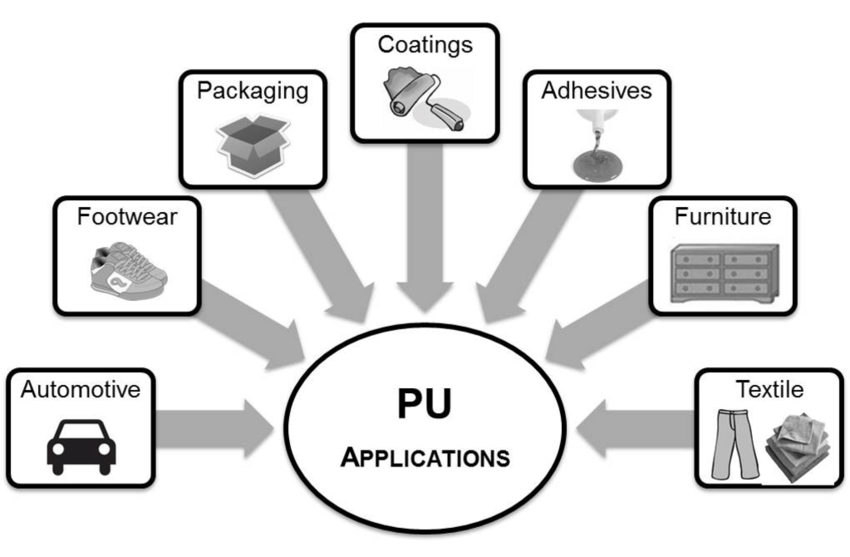

- polyurethane and its uses.

Then, followed the analysis of the key factors that can influence our thermoforming process, quoting a few more relevant:

- The quality of the material;

- Control the heat addition;

- The mold shape;

- and the vacuum.

In practice, we translated that knowledge into appropriate machine settings, reducing errors and waste less material.

Impactful results

Confidence + knowledge = better results

By investing in knowledge, we give our people the tools and trust to act with confidence, and get the desirable results that are expected from the equipment.