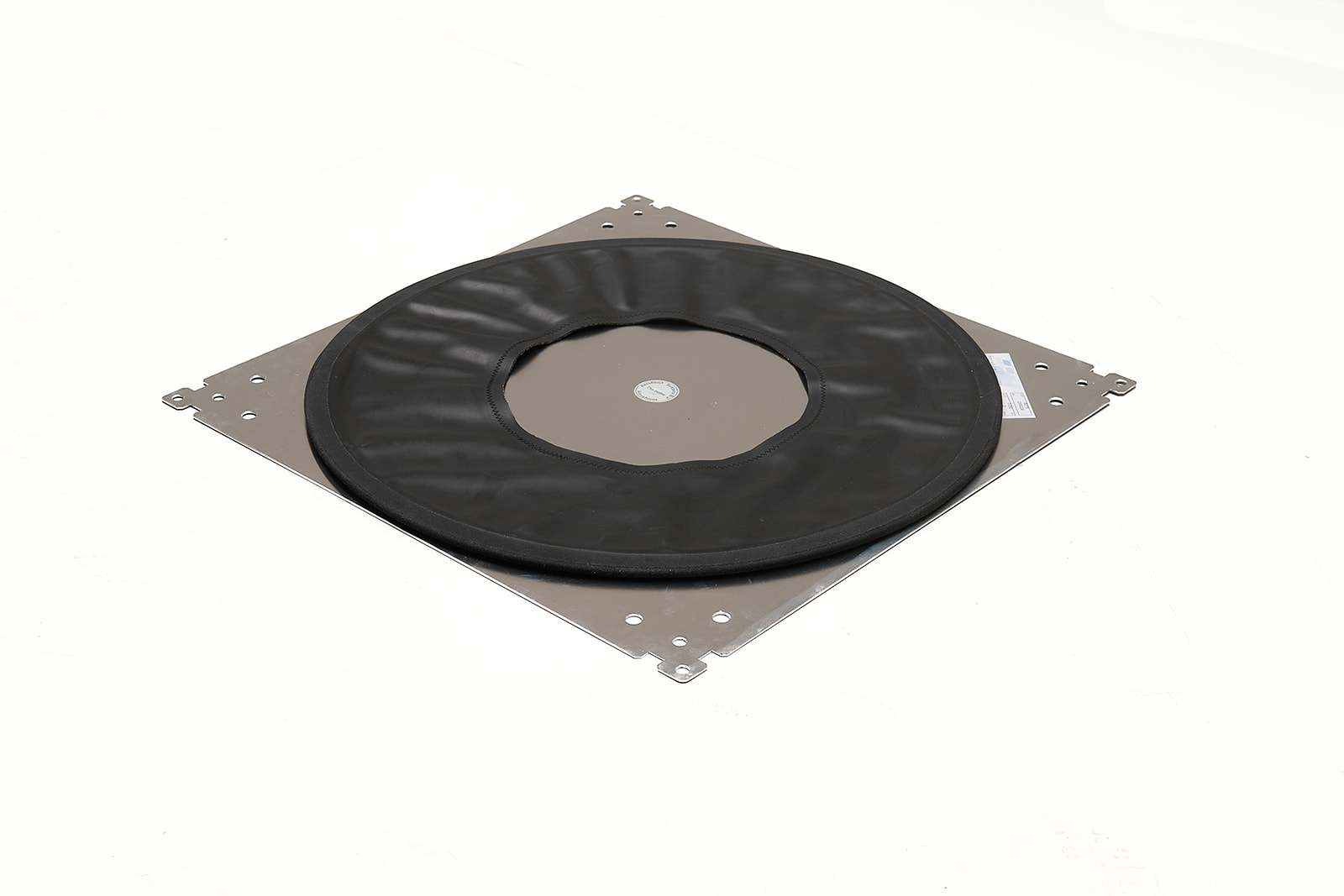

Features

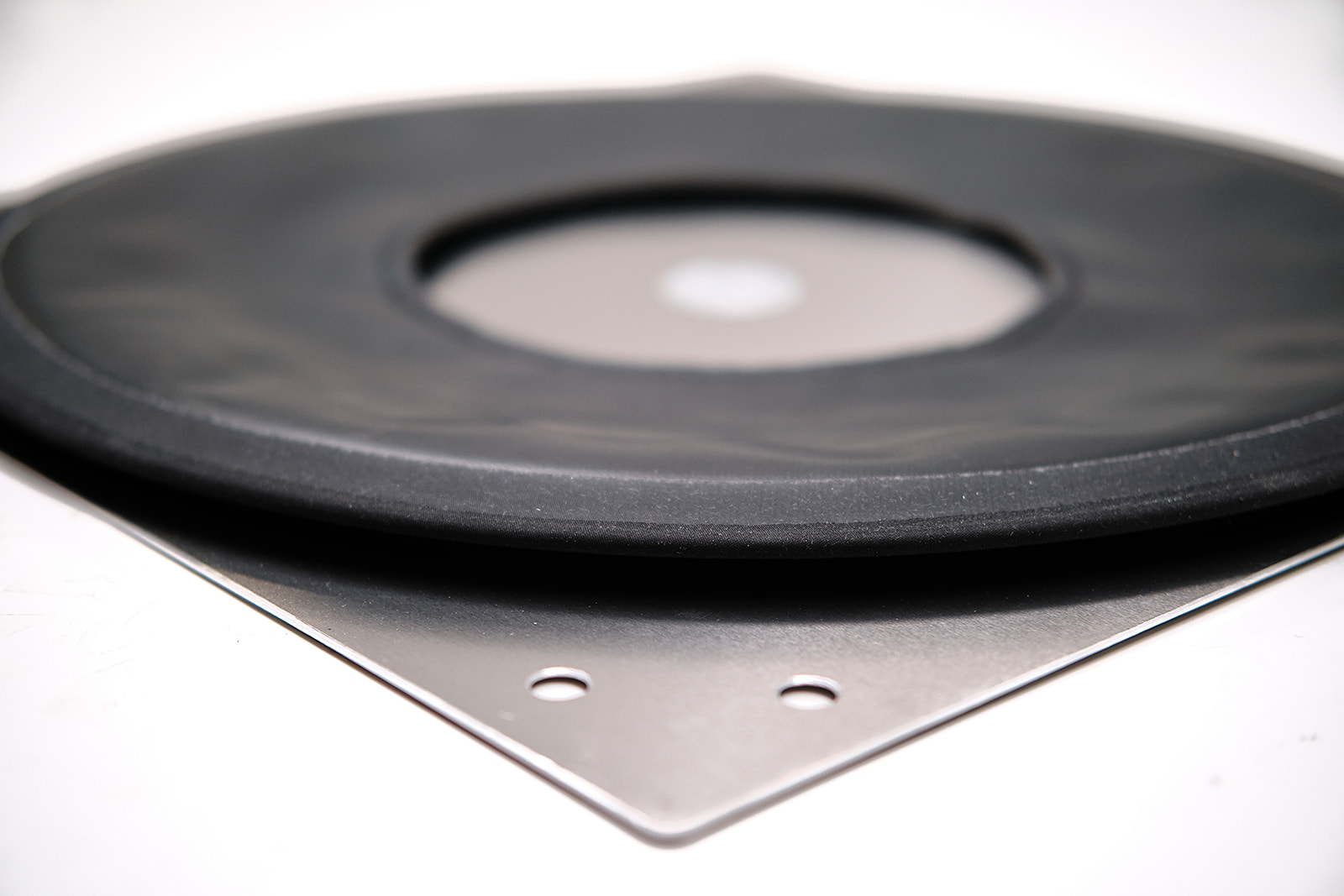

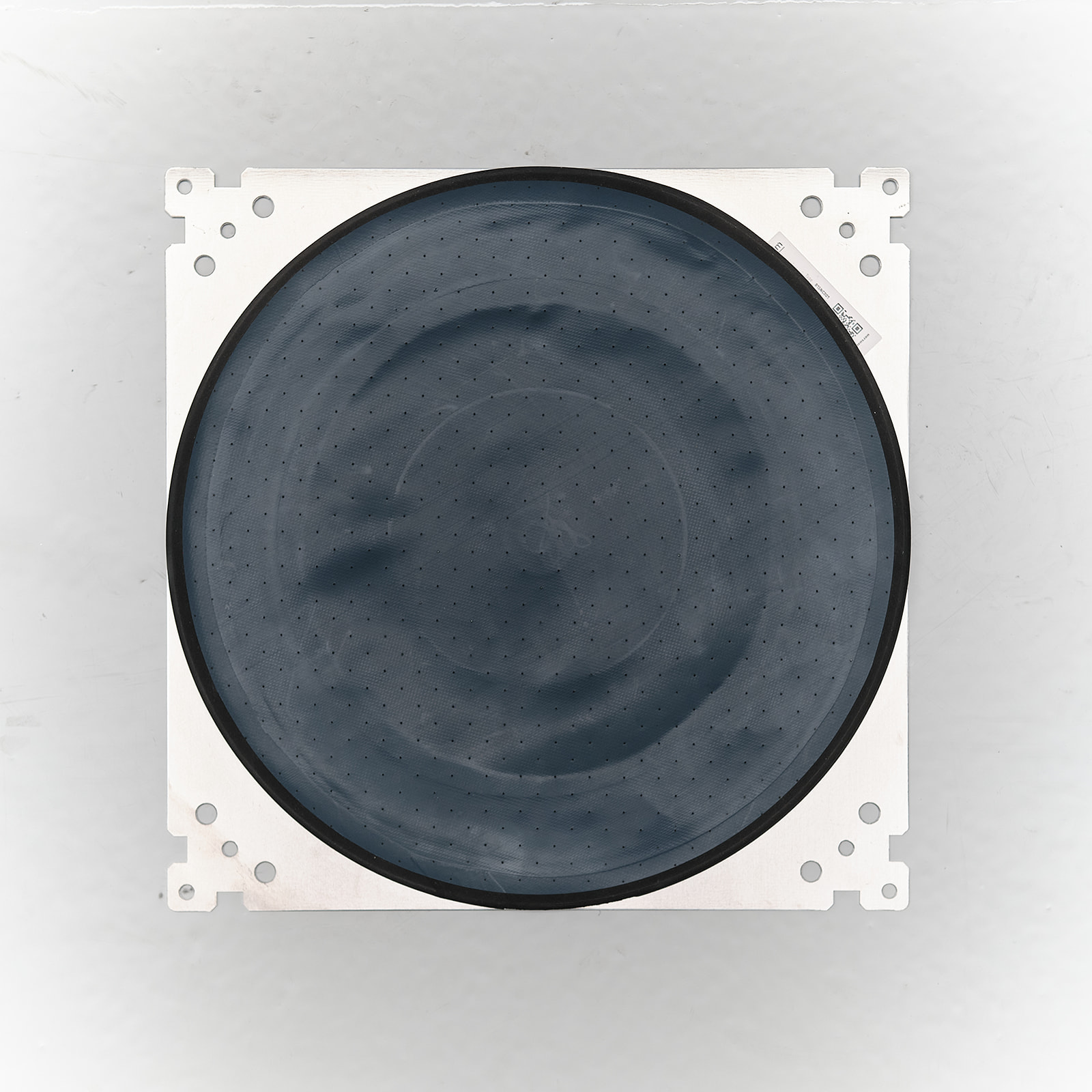

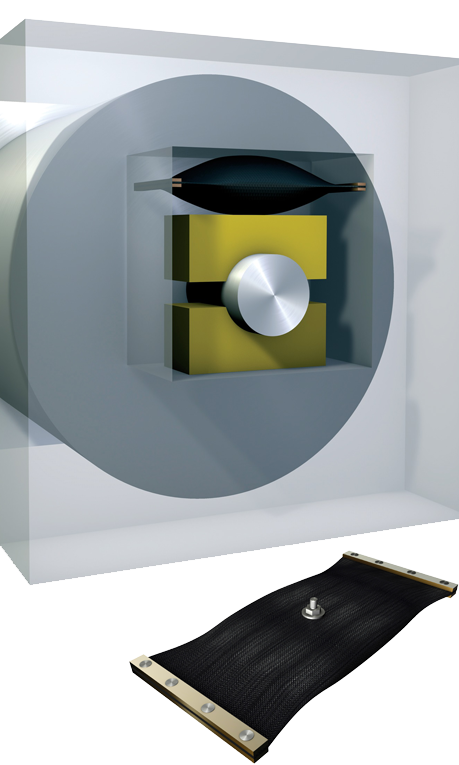

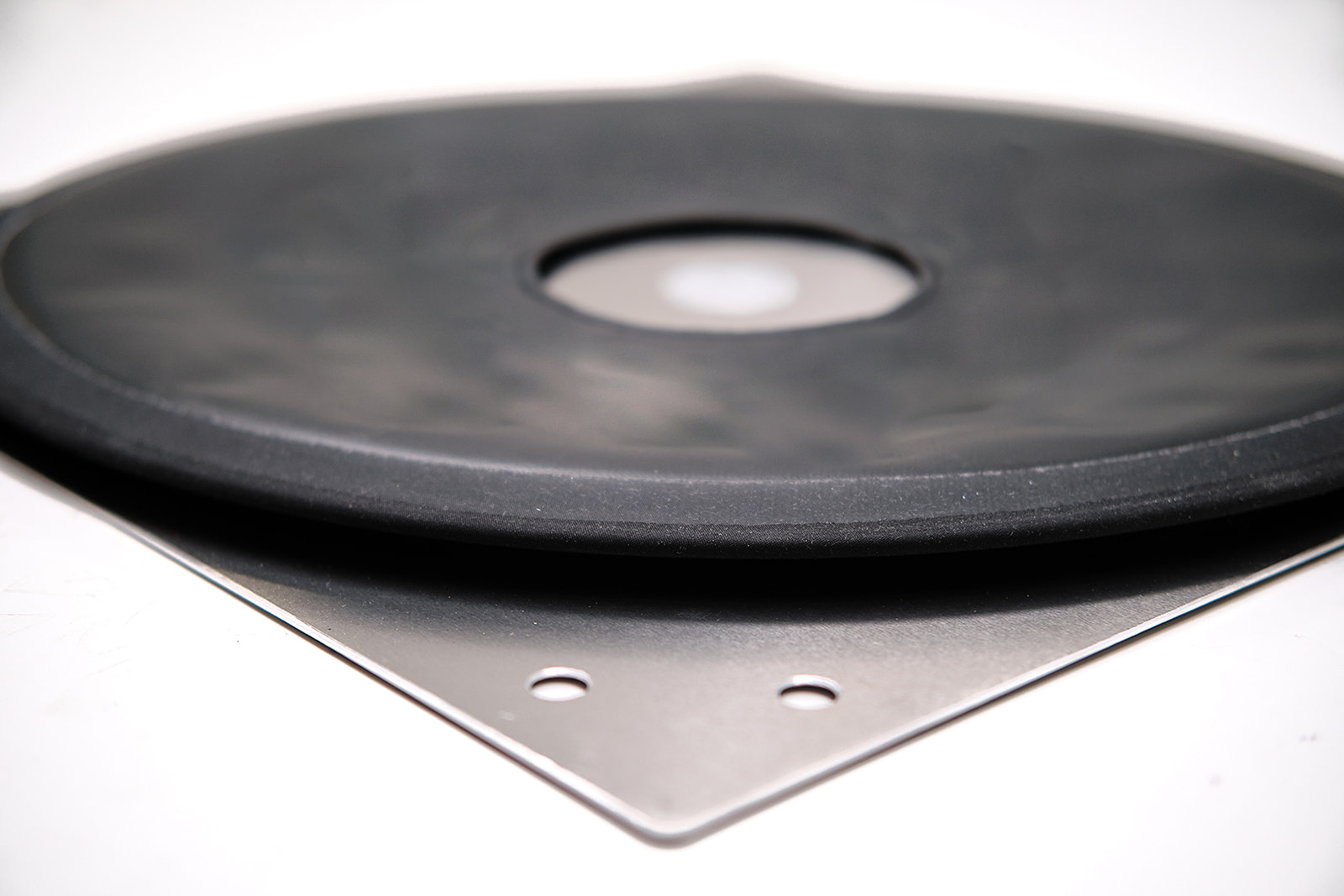

Neoprene is one of the strongest materials used for air casters. Key features:

- Higher pressure. The strongest material in the industry allows for higher pressures in the air caster membrane.

- Robust construction. Widely applicable due to its strong build, making it suitable for various industries.

- Higher lift. Due to its design, it achieves a higher lift than a polyurethane air caster of the same diameter.

- Various sizes available. Available in diameters up to 150 cm / 60 inches.