What are Air casters?

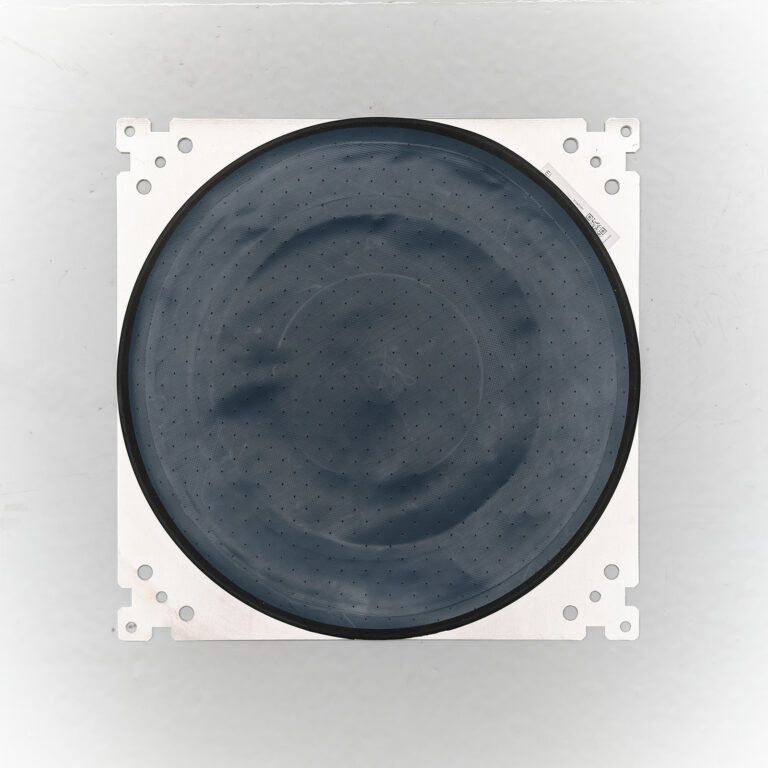

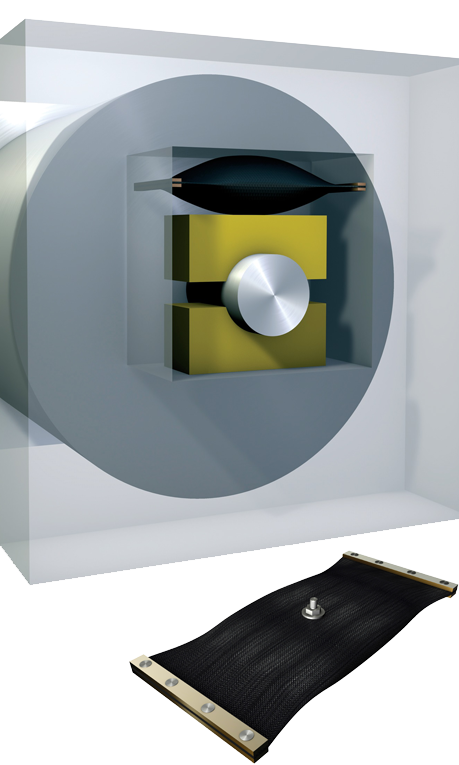

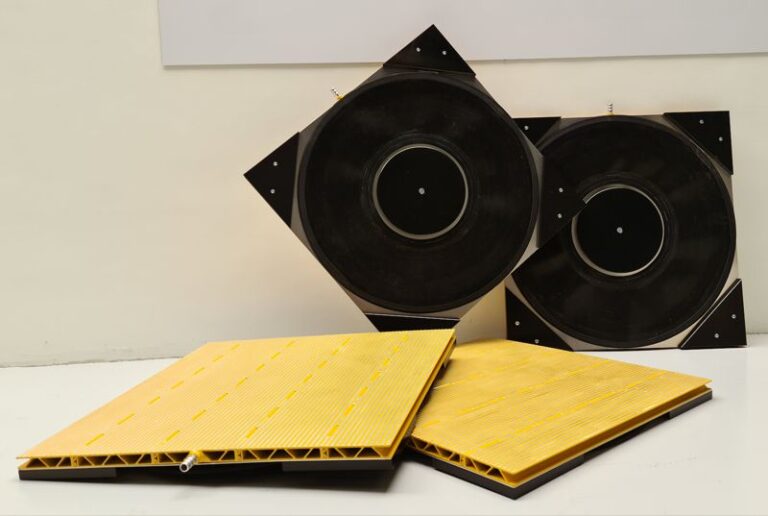

Air casters allow you to move heavy objects with ease. The object floats on a thin film of air created by controlled airflow through the membrane.

This air film reduces friction between the object and the floor to just one-thousandth of its original value. As a result, you can move heavy loads, such as machines or other equipment, effortlessly and efficiently.

Because the load is evenly distributed, there is minimal risk of damage to the floor or the object itself—making air casters an ideal solution for flexible and efficient internal transport.